Wholesale Summer Cycling Socks Cotton Sorts Socks for Ride Bike

The production of cycling socks begins with fiber selection. It uses high-performance materials such as polyester, nylon, cotton, and merino wool for composite weaving, taking into account moisture absorption, quick drying, and wear resistance. In the spinning stage, high-density yarns are formed through processes such as opening, combing, and drawing to ensure fabric uniformity. The sock body is knitted with a jacquard machine to complete the three-dimensional structure, such as the gradient compression design at the arch of the foot and the elastic wrapping module in the Achilles tendon area, combined with seamless stitching technology to reduce friction. The shaping process uses high-temperature steam shaping technology to ensure that the sock shape fits the foot curve, and at the same time, elastic strips are implanted to enhance the stability of the ankle joint.

The production process of riding socks must pass four core quantity inspections: yarn strength test, seam head fastness sampling, color fastness verification (up to national standard level 4) and tensile resilience evaluation. The finished product must comply with FTPM (functional textile performance certification) and Oeko-Tex Standard 100 ecological textile standards to ensure that there are no harmful substances left. Some high-end products also need to pass ISO 9001 quantity management system certification to ensure that the entire process is traceable.

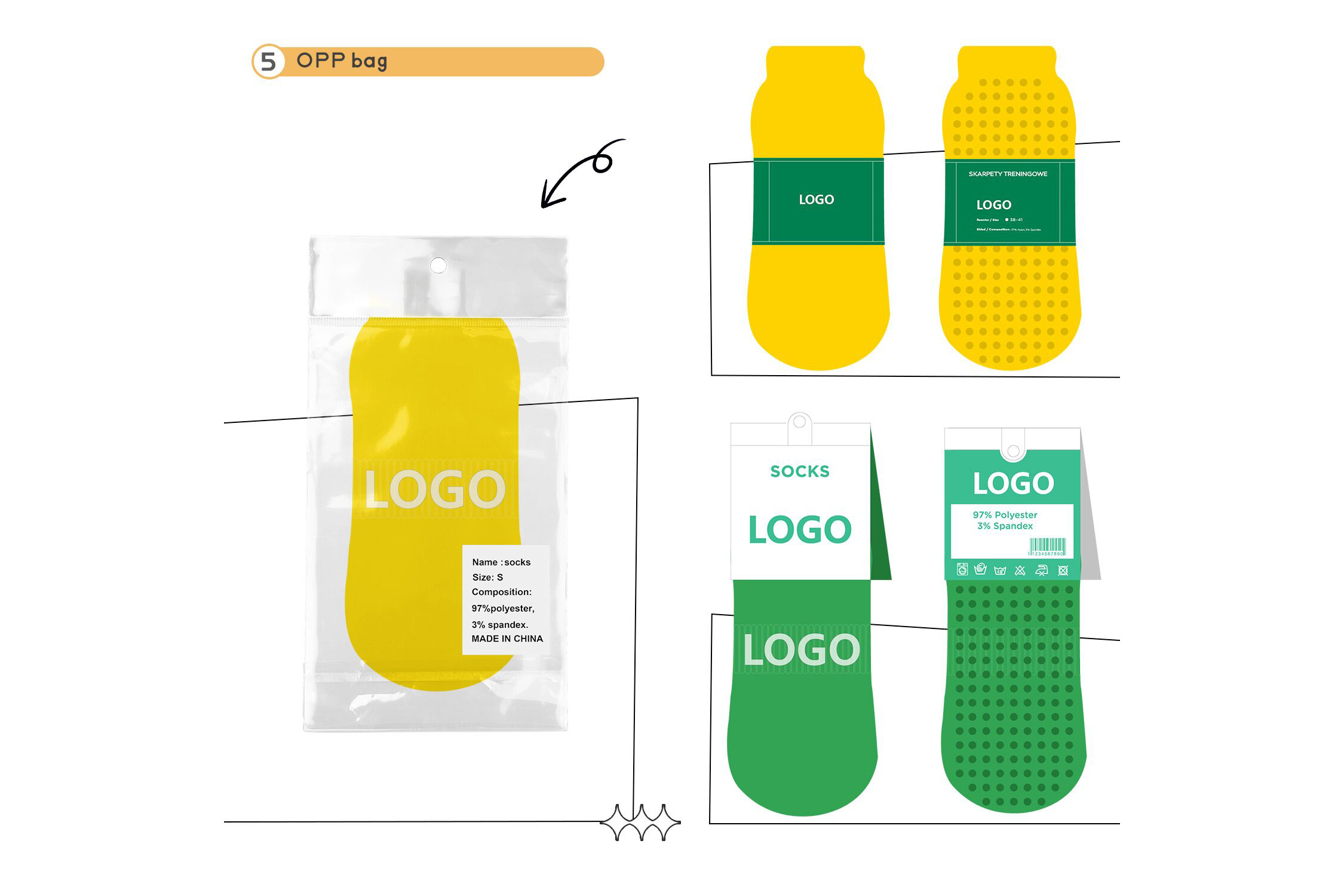

Cycling socks are optimized for long-distance cycling scenarios. The thickened shock-absorbing area on the sole relieves pedal impact, and the breathable mesh is distributed on the metatarsal and Achilles tendon to accelerate heat dissipation. Customization services support LOGO embroidery and thermal transfer technology, and brand logos can be implanted in non-stress areas such as the sock opening and the instep. The packaging uses biodegradable materials and supports independent boxing or environmentally friendly bag packaging to meet the needs of event souvenirs or corporate gifts.

Trampoline Socks

Trampoline Socks Aqua Park Socks

Aqua Park Socks Grip Football Socks

Grip Football Socks Basketball Socks

Basketball Socks Badminton Socks

Badminton Socks Cycling Socks

Cycling Socks Running Socks

Running Socks Disposable Socks Bowling Alley Socks

Disposable Socks Bowling Alley Socks Disposable socks

Disposable socks Warm Colorful Striped Crew Socks for Women

Warm Colorful Striped Crew Socks for Women Custom Unisex Crew Socks Breathable Socks

Custom Unisex Crew Socks Breathable Socks Digital Printing Vintage Crew Socks

Digital Printing Vintage Crew Socks Animal Fuzzy Cartoon Crew Socks for Women

Animal Fuzzy Cartoon Crew Socks for Women Cotton Flower Ankle Socks Low Cut Socks

Cotton Flower Ankle Socks Low Cut Socks Thick Christmas Festival Crew Socks

Thick Christmas Festival Crew Socks Cotton Cute Anti Slip Baby Ankle Socks with Cartoon

Cotton Cute Anti Slip Baby Ankle Socks with Cartoon Colorful Soft Baby Socks Anti-slip

Colorful Soft Baby Socks Anti-slip Non Slip Soft Ankle Baby Toddlers Socks

Non Slip Soft Ankle Baby Toddlers Socks Cartoon Baby Socks With Grips Crew Walking Socks

Cartoon Baby Socks With Grips Crew Walking Socks Baby Socks Floor Grip Mid-tube Socks with Cartoon

Baby Socks Floor Grip Mid-tube Socks with Cartoon